Building a Clayton 2" Scale Steam Wagon

designed by Robin Dyer

built by Tony Simons

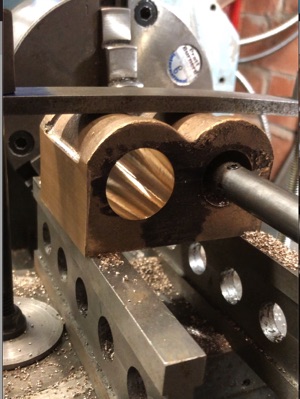

Cylinders

It was decided the best way of ensuring concentricity of the bores was to line bore them. First job was to make a boring bar, a simple job using a piece of 3/4" bar and an HSS tool bit. Then to find a way of clamping to the cross slide of either lathe. The only way I could use the Harrison would be to buy a T Slot table and bolt it to the cross slide. The Boxford did however have 1 T slot. The top slide is held on using a taper machined on the underside and clamped by taper wedges. I mimicked that arrangement but with a stud in the top.So now I had a way of clamping to the cross slide.

Next job was to machine some datum faces on the casting. Once that was done it was set up on the cross slide and I bored the cylinders. Once one was done, it was easy to set the cross slide over to do the second. The final operation was to put a face cutter in the lathe spindle and face the end of the casting to ensure it was at 90° to the bore. The video shows the operation in progress.

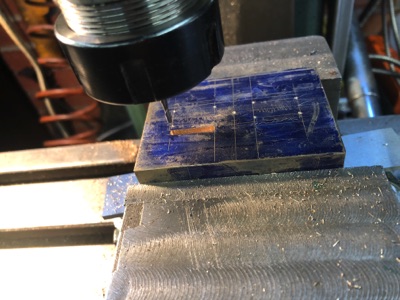

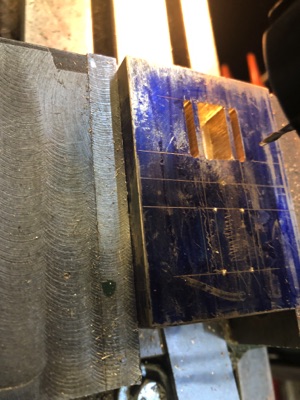

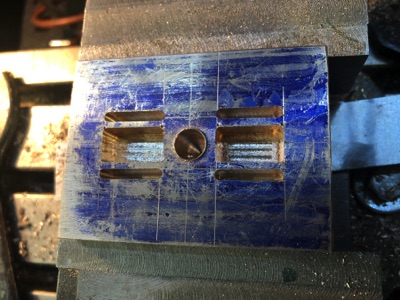

Next stage was to machine the steam ports in the valve chest face. Marked out and milled to size. The the steam passages had to be drilled. Working out the angle was made easier by using a device nicknamed a "Gribbopredictor!" By arranging the points of the device at the entry and exit positions I could measure the angle required. I then tipped the head over on the milling machine to the same angle and drilled the ports.