Building a Clayton 2" Scale Steam Wagon

designed by Robin Dyer

built by Tony Simons

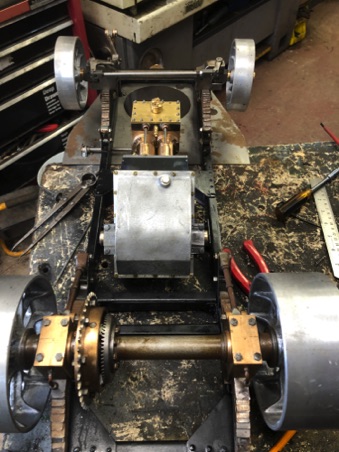

Crankcase

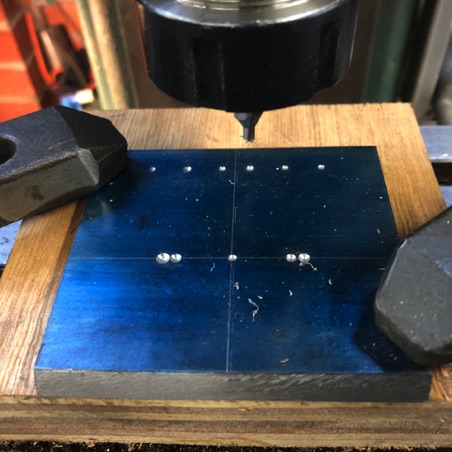

The crankcase is a fabrication from 3mm steel sheet. It carries various bushes for things like the waterpump, valve shaft etc. The main bearings bolt to it. It is fastened to the cylinder mounting plate and supported at the other end by the engine bearer. As the main bearings bolt to it everything has to be inline. A complete nightmare! A flange is secured to the bottom face again made of 3mm steel to provide a bolting face for the sump. These are fastened together by a series of 10BA countersunk screws. What a pain drilling into the edge of 3mm plate to tap 10 BA holes!

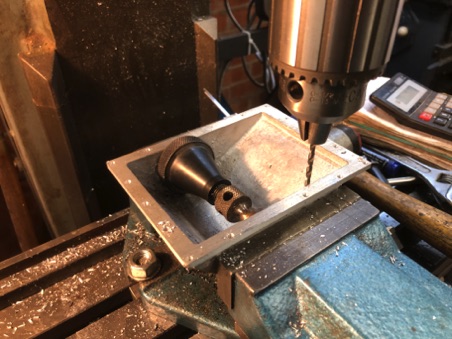

The crank centreline is not on the dge of the sump face but 1/4" down. A 3/16" hole was drilled in this position whilst the plates were clamped together for drilling and shaping. I made a dummy crankshaft drilled & tapped either end for 2BA and bolted this in place. Mounted the engine bearer next and that meant I had a rigid structure to bolt to the cylinder block end plate.

I made a jig tha clamped in the bearing with a 3/16" spiggot to fit the hole in the crankcase and used that to allign the br=earing housing, I drilled through the crankcase into the main bearings, tapped the holes and bolted the housing in place. The crankcase was then filed out to match the bearing housing. The bearings were installed, I hadn't reamed the bearing when I made them to allow me to ream them in situ.

Assembly was tricky but it happened! The sump face was machined flat and then drilled for the flange bolts, note the use of a machinists jack to avoid cracking the sump. Various covers were made and the engine mounted in the chassis.