Building a Clayton 2" Scale Steam Wagon

designed by Robin Dyer

built by Tony Simons

Differential

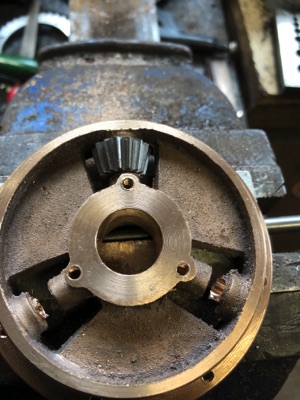

The design is 'borrowed' from an Alchin Traction engine and the drawings were not complete referring you to the Alchin drawings, luckily someone in the York Model Engineers had the drawing. So having checked that the gears actually meshed correctly, confirming I had machined the rear axle to correct dimensions, the next step was the pinion carrier. Careful marking out and machining was required here to ensure the 3 bevel gears mated correctly with the crown wheels. I first machined the outside diameter of the flange and faced it, then I bored the hole for the axle. Reversing it in the chuck I machined the register for the chain sprocket.

I mounted the carrier in a chuck on the dividing head and set up the first pinion shaft vertical and ensured the bore was on the centre line of the machine spindle. I drilled the first hole and reamed it, then indexed 120 and did the same again and finally indexed another 120 and completed the final hole. Next I drilled the holes for the retaining screws for the pinion shafts.

The sprocket was a commercial one that I modified by boring out the centre to fit the carrier. The holes to fasten it were again drilled using the PCD function on the DRO. That has been a godsend, saving so much time marking out. The final photos show the axle assembled.