Building a Clayton 2" Scale Steam Wagon

designed by Robin Dyer

built by Tony Simons

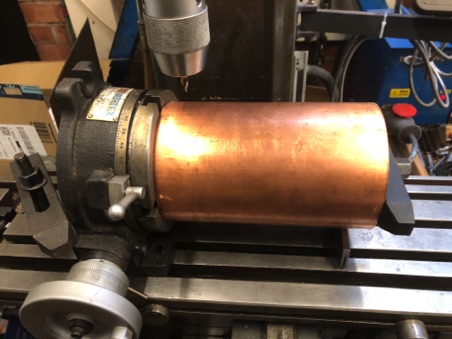

Boiler

Time to make the boiler! I used the rotary table mounted vertically to mark out the relevant bushes as they were positioned at 30° and 45° from the datum. I turned the former for the tube plates and drilled 1/8" holes to locate the tubes, 35 holes laid out using the DRO. The tube plates were then flanged and drilled. Various bushings were silver soldered into the barrel. The clinker hole tube was made and fitted to the inner firebox. Its used for removing clinker and stirring the fire as its fired from the top as Steam Wagon Practice. The tubes were reduced at one end by 1/64" the firebox tube plate being reamered to suit. This prevents the tubes falling through on assembly, The tubes are cut a different lengths to facilitate assembly. The tubes were silver soldered into the firebox plate and the firebox barrel. Next a piece of 3/8" square cooper was formed to make the foundation ring and the whole thing trial assembled again. Then the big heat to silver solder it!