You will doubtless recall that the engine, so laboriously removed, had been sitting on a trolley under a blanket for some time. The time had now come for action on that front so one sunny day in spring I drove over to Leeds and bought an engine stand, a big flat box full of impressive looking beams.

Happily it was light enough to move around and the instructions were good enough even for me, so soon it was standing in the middle of the garage waiting for its load. No problem! Swing the engine up on the engine crane and offer the back end up to the relevant fixing points, then- ”Ah! No bolts long enough". No problem, Tony‘s got enough bolts in his garage to supply Screwfix. One phone call is enough. He was coming the next day to help with the dismantling anyway.

On the day we soon sorted out a number of suitable bolts complete with packing of all sorts to make them fit. Make a note to get new, correct bolts next time. (What next time? Ed). The engine was offered up again and bolted securely to the engine back plate, (after removing the flywheel). Then we took it off again and removed the back plate which turned out to be the next step and with a different set of bolts fixed the lump to the stand. I must say that at this point the effort was worth it. Total access and rotatability achieved.

After that things get blurred for a while due to your editor‘s habit of whipping things off and chucking them all in one big box, bolts and all with a merry cry of ”Don‘t worry, I know where they go".

The head was wrapped in a curtain and placed on the bench, soon to be followed by the crankshaft which went into the boot of the Rover for want of space.

The camshaft assembly looked good and was oiled and wrapped and stored carefully. The pistons came out and were junked since the bores were obviously poor and lo and behold the engine was in bits. Actually in hundreds of bits most of which were overflowing the cardboard box and spilling over the floor. Nuts, bolts chains, ancillaries all mixed. A three dimensional jigsaw of which more later.

Now I can‘t machine things but I know a man who can, so off went the heavy bits to Best Engines in York. The crankshaft was reground and provided with new shells, the block was rebored and new pistons and rings supplied and, after I dismantled it with the valve spring compressor, losing bits like confetti on the way, (remember the time wasted looking for the collet and a bloodied nose?) the head was skimmed and the valves and seats were refaced. (No I didn‘t get it sorted for unleaded, what do you think I am, clever?)

And so, on yet another sunny Saturday we started to reassemble. It‘s a doddle on the stand really. With the ability to rotate the block as you wish there‘s little physical effort and all attention can be focussed on not lashing anything up.

Having seen the inside of Peter Humpherson‘s side plates I had bought a new set to fit as a matter of course. When they came off we were faced with a good deal of sludge half filling what look like barely adequate waterways round the cylinders so we wheeled the stand out into the sunshine and fitted up the pressure washer which did a fine job of totally cleaning away the gunge. Sadly, during this activity, my wife came up behind us to deliver some message and as I was startled by the call I turned round quickly and discovered what happens when one‘s nearest and dearest gets the full force of a pressure washer straight over the Saturday best outfit. For the benefit of the squeamish I draw a veil over the consequences.

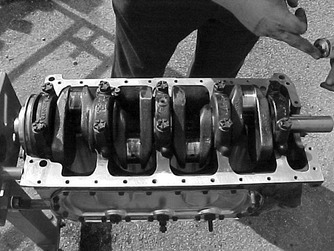

The side plates fitted easily as did the pistons without breaking any rings. This probably because Tony did that bit. Then swing the engine over and fit crankshaft and bearings, no problem. All bearing surfaces were well coated in Graphogen paste to keep the dreaded rust away and protect them whilst the oil pressure builds up. On with the sump and there‘s only the head to do.

What is this only? Of course the valve clearances were totally upset by the machining and to reset them on a P6 is a nightmare involving much trying of shims and constant refitting of the head. Fortunately one of our branch members Tony Huntington had, only the previous week, come up with the jig for valve setting which he found in a garage and donated to the branch. Even so, the head has to be fitted to this jig at full torque every time you want to measure the results of the latest attempt at setting.

We were hampered by the fact that we only had the shims which came out, together with a tobacco tin full, courtesy of Barry Swallow, which by no means made up a full set. It didn‘t help that we were fitting up imperial clearances with the help of a metric micrometer to measure the shims. The maths is quite interesting involving much heated debate. Some had to be taken down several thou (or was that tenths of a mill?) on an oilstone and I can tell you they are hard, very hard.

It took a long time but it got done and the head was triumphantly refitted. Then we took it off again because the engine would only turn three quarters of a revolution before a valve clearly hit a piston. It transpired that one shim had been displaced to lie cornerwise in its place giving that valve a large negative clearance.

I‘m personally a bit unclear about the next bit because it involved Tony fitting the new timing chains which seemed to involve dipping his hand into the box and extracting bolts at random. There must have been some method in it because the job went really well and everything fitted. Then he pulled out the plastic tabs from the tensioners, which is the last act in a long job, and one of them broke and couldn‘t be extracted so he took it all to pieces and did it again. Judging by his language the strain was beginning to tell so if you saw him at Sledmere I hope you were kind to him, he may not have recovered yet!

With the major stuff done Tony retreated and the ancillaries got cleaned and fitted over a couple of weeks so now the engine hangs proudly from its stand awaiting refitting.