A deep depression over Poppleton

with sunnier spells later!

Easter. What a glorious opportunity to get four straight days work on the P6. Enough to get well on the way to completion! Well it would have been had it not been for the one step forward, two steps back routine!

The master plan (insofar as such a thing exists in this project) was to finish the electrics, vinyl the roof, fix the choke, add the exhaust, fill with petrol and start!! Who do I think I‘m kidding? For a start I‘ve noticed that when the crunch comes I tend to shelve the heavy, dirty jobs and I well remember countless hours under various old bangers trying to separate exhaust components. OK then - I jacked and propped up the car and acquired the bits in advance to allow no excuse on the day. Except of course that the motor factor couldn‘t come up with the middle box. The old, slightly holed job would have to do.

Overalled and tooled up I finally got underneath with the exhaust bits and a pre-prepared set of cleaned and tapped nuts and bolts only to find that the manifold and front pipe had entirely different ideas as to where under the car they should meet. With the box offered up to its fixing point under the gear box they could be persuaded to touch but would approach only at an angle. Nothing daunted I ladled on cement and tightened up the bolts as hard as I could. You wouldn‘t call it gas tight but it was approximate! The middle box shed a lot of red dust when handled (mostly over me) suggesting that there may be little in the way of baffles left, but superficially it looked OK so I cobbled that on as best I could and then added the rear bit. It dawned on me half way that as long as the engine started I could call at the exhaust shop on the way to the MOT and with any luck they would be committed before finding out that the bits seem to have a positional sense all their own.

This all took a good deal more time to do than to tell, so I wasted the rest of the morning attaching wires to various side lights and finding that none worked. At least not until it dawned that one should have the ignition on. Then it went better. I even got the headlights to work.

After lunch the roof! This was supposed to be easy according to a little article I fount in a recent Practical Classics. In fact it wasn‘t too bad except for the bits they never mention. I remembered to prepare the roof by treating all the rusty patches and rubbing the whole lot down and cleaning it with alcohol wipes. Then I folded the pre cut vinyl and laid it across the panel. Spray glue was applied to the roof and cloth in equal measure for about a foot and allowed to dry. This is where the first unmentioned cock up occurred. If you don‘t mask the unfolded vinyl you get a fine overspray of glue across the roof. Still it won‘t show when it dries will it? The cloth is sufficiently flexible and the curves gentle enough that no stretching is needed as it goes on. It‘s just like brushing wallpaper on. In fact I used my wallpaper brush. Proceeding in smallish section I got the whole flat roof on fine. Only the edges and overlaps to go. Easy, just turn the roof over and rest it the other way up. Smart thinking suggests padding so as not to damage the surface so I used a couple of pieces of that furry underlay stuff which provided excellent padding and soon had the reveals stuck. On turning the roof over again I discovered that glue which appears dry is not necessarily beyond sticking. Indeed if you think about it you don‘t put the bits together till they seem dry. Do you remember those suede covered cars of the sixties? Well now I know how they did it. My roof had a nice hairy coconut finish in a stripe right across the middle. I reckon if I leave it long enough I can brush it all off. If not I‘ll have to shave it and boot polish it.

Much disheartened I abandoned for the day and resolved to start the engine the next day to make up. Fat chance. For a start the choke wire was missing and evaded detection for ages till I banged my head on it. Then the end was wrong and finally when offered up I couldn‘t get my fingers in. The rotating bit to which the cable fits was jammed solid and resisted all efforts with pliers and Plus Gas to move it. It was so hard jammed I felt some physical obstruction was the only explanation so I took the inlet manifold off. This took long enough for the Plus Gas to work and the choke was free as a bird, so I put it back. I spent an age fitting the heat shield and again gave up for the day. Two days and no further on.

On Sunday I took courage and poured some petrol into the tank. At first I added only the odd egg cup full looking all the time for the inevitable leak, but no. The whole gallon and no leaks. Great! Pump priming required much sucking at disconnected lines but once fuel filled the pump completely it successfully pushed petrol to the twin carbs with ease and still no leaks. So now for the big one. Pull the choke and spin it over! No go! For a start the jubilee clip holding the inter carb fuel line fouled the choke. I couldn‘t reach it as it was, so I mostly removed the air cleaner and carbs again and then put them back. Try again. No go - the starter won‘t turn. It took the rest of the day and a lot of swearing and testing of bits of wire before I discovered that the engine earth strap wasn‘t conducting and needed brightening. Day three a write off I think.

On the Monday at least the starter turned the engine well. That however is as far as it went on the starting front. I opened the cover on the fly wheel and lined up the timing marks as in the book but for some reason the relevant cylinders were not at the top. Hours and hours of fruitless turning with a big socket on the crankshaft bolt produced nothing but puzzlement. So I gave up and had a drink and on Tuesday I went to see Barry who listened to the tale as one listens to the village idiot and then took me upstairs to his garage store room and showed me the marks on the pulley from which TC engines are timed and the pointer against which they should line up. Whoops!

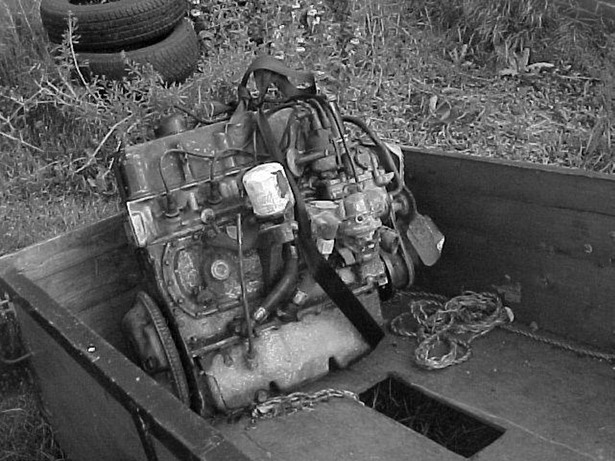

Back home I did as instructed and still no go. So I rang Tony who was kind enough to point out that although Henry Ford may have fired his engines 1 2 4 3 , Rover stuck to the more common 1 3 4 2. Deep embarrassment. And still no result. So Barry gave up and came to fix it a week later. In the meantime I kept trying and the engine kept getting tighter and tighter until the starter could barely move it and it sounded like a bag of nails. I was sure it was seizing and would be ruined. I got so worried that when Plan B in the shape of another 2.2 engine, fell cheaply my way I snapped it up, sure it would be needed. Barry gave the starter a cursory turn, reconnected the wire which I had dislodged from the starter and carried on.

Paul Driscoll came too so no shortage of hands and Barry admitted that I‘d at least finally got the timing and leads right and commenced to churn the engine . The idea seemed to be that if you turn the key and keep it turned, sooner or later the engine will get the message and go. And indeed as he altered the timing a bit we gradually got some firing. It stopped when the key was released but at least it fired. More timing adjustment and much plug cleaning later and the engine was going under it‘s own steam. Then moving the distributor achieved almost a smooth run at which point the front carb flooded and dumped about a pint of petrol on the, by now, hot exhaust. Paul, with great presence of mind, ran away whilst Barry appeared unconcerned. (Well his party trick is to put out a cigarette in a dish of petrol to prove how non-inflammable it really is.) As for me, I had visions of the great fire of Poppleton and howled for him to stop. Clearly the carb had to come off and the whole dismantling process was undertaken again. And there it rests for now since the York Branch Spring Weekend up on the moors prevented play this weekend. But that‘s another story of automotive disaster which must wait for another day.