Ever since the first heady days of dismantling the newly acquired car, two gearboxes have been standing side by side in a remote corner of the garage like two long forgotten tin soldiers. ”Why two?" you ask yourself. I asked myself the same question several times without much in the way of reply. Still it worried me. Why two gearboxes? Why would anyone bother to acquire a second box if the first was OK. Which was the second box anyway. Had the replacement been fitted? In that case the ”spare" one was the bad one. On the other hand was the good one waiting to be fitted? In that case the one in the car was duff. Seems like the occasion to take experienced advice.

Your editor was very helpful and clear on the subject. ”Don‘t worry, put it back as you found it and if it‘s wrong change it". Barry Swallow came up with the same advice and as they had both wet themselves laughing at my attempts at fitting the drive shafts I began to suspect a conspiracy here. Those with long enough memories to remember how I got the box out in the first place will understand my reluctance to have to do it again unnecessarily. For those not familiar with the P6 the gearbox has to go in and out attached to the engine. If I ever get the engine in and working I certainly don‘t want to take it out again. Barry told me about a chap in York who refurbishes gearboxes but he didn‘t have his number.

So, one sunny morning, I went back to Best Engines to ask if they do gearboxes. They don‘t. ”However" says Mr Best ”I know a man who does and he‘s standing ten feet away as we speak!". Brilliant. This turned out to be the very man Barry told me about the day before so a deal was struck on the spot and the box delivered to him later that day. It came back a week later having had two bearings replaced. One main bearing because it was worn, (even I could feel it rumble as I rotated it) and one, a nylon caged roller bearing between the input shaft and main shaft, because it was well and truly shattered. If ever a few quid was well spent then this was it. Except that the doleful message that the universal joint at the rear of the box was shot came with it. Since he wasn‘t within earshot at the time I couldn‘t ask why he hadn‘t changed it.

Since the sad demise of my old vice I had been out and bought the biggest engineers vice I could carry. In fact I couldn‘t carry it far, I had to take the car into a no go area to load it rather than carry it across York. This monster made short work of extracting the UJ and a comparison at the motor factors produced the correct article in no time. Confident in the knowledge that nothing could break my new vice I lined everything up with suitable drifts and sockets and applied serious welly to the vice which performed magnificently. Sadly not so the bench which broke most impressively. The whole of the front beam came off. Still I‘m better at woodwork than engineering. Once re-attached the vice inserted the UJ in no time.

A nice shiny new clutch kit had arrived earlier and now needed fitting. I once did this on a mark one Ford Escort (yes I know but I was young then) and managed well with a bit of broom handle bound up with sticky tape to the correct (roughly) dimensions but this seemed somehow inappropriate so I borrowed Tony‘s kit. This comes in a large wooden box with many bits so a preliminary tutorial was needed. As this took place in the pub one Thursday night it‘s value was dubious but it turned out to be fairly simple anyway. The gearbox slid gracefully into the splines until about half an inch short of complete mating and stopped. This puzzled me for a while but nothing daunted I fitted the bolts and pulled it into place gently. Then I took it off again because I forgot that the two bottom bolts go into the alloy sump and require UNC bolts not UNF (no I couldn‘t find the originals, they‘re in the garage laughing at me somewhere). (Much like the rest of the club. Ed). This seriously damaged the thread which I was lucky enough to restore with a UNC tap. Before replacing the box I mentioned the half inch discrepancy to the lads in the pub who laughed like drains and told me I‘d got the clutch plate on the wrong way round. Oh ye of little faith! Nothing but a tight fitting spigot bearing. There was no problem second time round.

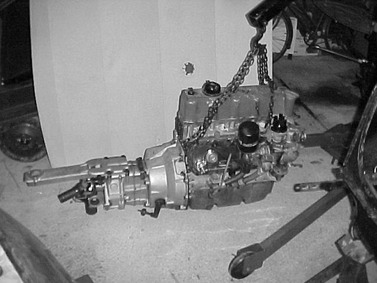

So now there‘s a huge engine/gearbox complex sitting on the floor with most of the ancillaries attached. It just needs carbs and exhaust, alternator and a few brackets and in we go!